Company Profile

Hebei Jingye New Energy Technology Co., Ltd. (abbreviated as "Jingye New Energy") was established in 2023. It integrates the R&D, manufacturing, sales, operation and maintenance services of core products such as large-capacity battery energy storage systems, EV battery PACK, and CCS (Cell Contact System) . The products are widely used in smart grids, wind-solar-storage system, industrial and commercial energy storage, green transportation and other fields, providing one-stop energy storage system solutions for customers in the new energy industry.

The products are applied in fields such as new energy power generation, smart grids, electricity consumers, and green transportation. The company has adopted the most advanced and highly automated production line in the industry and is committed to creating high-quality energy storage.

5 GWh

5GWh module PACK integrated production line

2.4million

The annual production capacity of CCS is 2.4 million pieces

5 MWh

5MWh energy storage container system

Corporate Vision

Sharing intelligent energy solutions to benefit enterprises across the nation

Corporate Values

Innovation, Environmental Protection, Green Development

Our Advantage

Integrated advantages of the entire industrial chain

Advantages of large-scale and automated manufacturing

Advantages of multi-scenario and full life cycle services

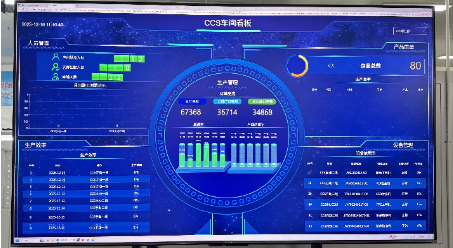

Jingye New Energy has always been deeply engaged in the forefront of the new energy industry. Relying on a complete industrial chain from the raw material to finished products, it fundamentally ensures the stability of product supply and cost advantages. Through highly intelligent production lines, it creates products with outstanding performance and consistent quality, which are deeply coordinated with the MES system covering the entire domain to realize full-process traceability and controllability of each product from materials to finished products. In addition, we have a senior R&D team and service system, which can provide you with one-stop solutions from technical customization to implementation support, greatly simplifying supply chain management and improving cooperation efficiency. Jingye New Energy always adheres to the concept of safety as the foundation and works with you to build a more stable and reliable new energy future.

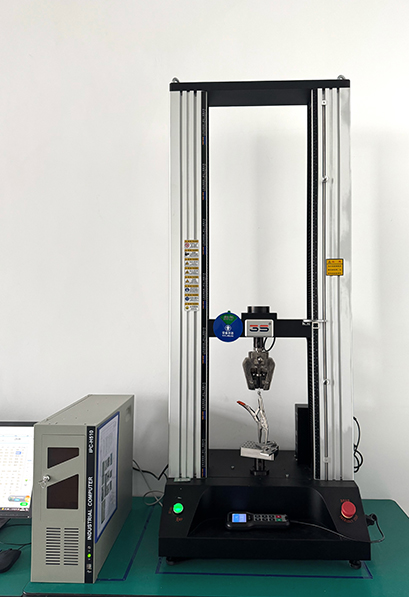

Jingye New Energy Testing Laboratory is the core support platform of the company's quality management system. Its CNAS-accredited facility ranks among the industry’s top in total investment, with hardware and technical capabilities both reaching advanced domestic levels.

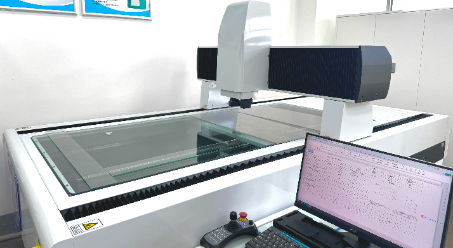

Equipped with over 100 sets of professional testing equipment, the laboratory features domestically leading key instruments, fully covering critical testing dimensions: physical and chemical analysis, electrochemical performance, safety and reliability, environmental adaptability, and precision dimension and appearance inspection. Among these, the automatic 2D optical measuring instrument—leveraging non-contact optical imaging technology—is widely applied to dimensional control of precision components, significantly improving testing accuracy and efficiency.

In the meantime, the laboratory has built a high-caliber testing team. Focusing on core links of the new energy industry chain, the team has established a full-lifecycle testing service system spanning incoming raw material inspection, in-process component testing, and end-product type testing. It delivers scientific, impartial and accurate technical support for a full range of products including energy storage battery systems, power battery systems and CCS integrated busbars, laying a solid foundation for the company’s product quality improvement and technological innovation.

Quality Control

alt="Inspection equipment"

Inspection equipment

CCD detection, AOI testing, functional testing machine, IR internal resistance tester, 2.5-dimensional withstand voltage tester.

alt="CCS"

CCS

When the raw materials arrive, they are first tested by manual vernier calipers, film rulers and other equipment. Then 2.5-dimensional pressure resistance tests and internal resistance tests are carried out on the appearance of the material, and finally the product is made and then CCD testing, AOI testing and functional testing are carried out on the line.

alt="Energy storage system"

Energy storage system

When the raw materials arrive, they are first tested by manual use of vernier calipers, film rulers and other equipment, and then 2.5-dimensional withstand pressure test and internal resistance test of the appearance of the material. After the pack is made, it enters the laboratory to test the charging and discharging and liquid cooling device.

Dedicated New Energy ESG Practice: Leading a Green Future

Partners

Certificate

Let’s Get Started on Your New Energy Journey.

+86 0311 6736 8615

+86 150 3207 1231