Dec 25, 2025

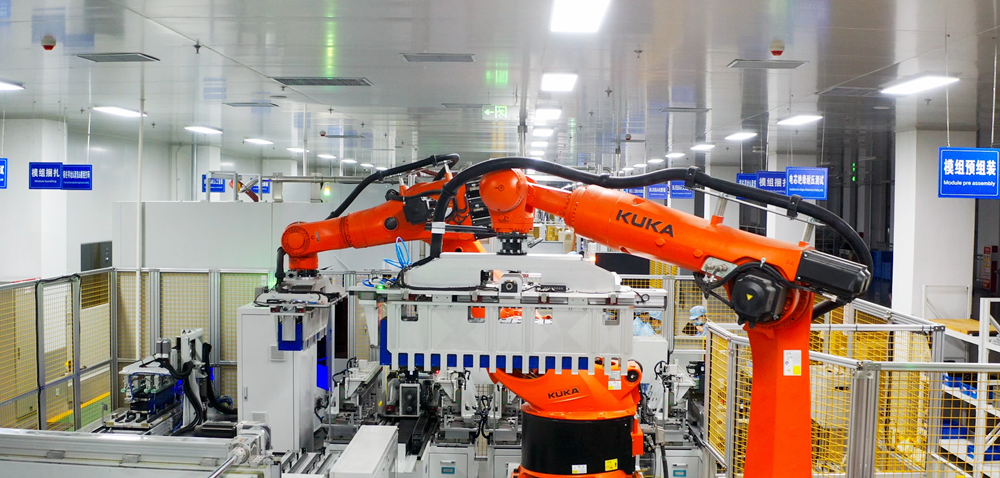

During the production and manufacturing phase, strict adherence to the quality management system and IATF16949 automotive industry quality management system standards is maintained, and high-precision manufacturing is achieved relying on intelligent production equipment. In the cell production link, robotic arms are used for automatic loading. The cell serial number is scanned, and the cell voltage, internal resistance, and other values are calculated through cell thickness measurement to ensure cell consistency. Module assembly adopts robotic arm-assisted extrusion, welding, and other processes to improve assembly precision and efficiency. During the integration phase, the connection between the BMS and the battery pack, shell encapsulation, and other processes are completed in accordance with the design drawings, and real-time collection and traceability of production data are realized throughout the process. The testing phase has established a "three-level testing system" to ensure product quality: the first level is incoming inspection of components, where comprehensive testing is conducted on purchased cells, components, structural parts, etc., and unqualified products are resolutely rejected; the second level is in-process production testing, where module performance testing (capacity, voltage consistency, communication function) is carried out after module assembly, and phased electrical testing and sealing testing are performed during system integration; the third level is factory system integration testing, covering full-item PACK function testing (status monitoring, charge-discharge control, protection function, communication protocol adaptation), safety testing (insulation resistance, voltage withstand testing, short-circuit protection testing), environmental adaptability testing (high-low temperature cycling, damp-heat testing, vibration and impact testing), endurance/energy storage performance testing, etc. Meanwhile, additional testing by third-party authoritative testing institutions is supported according to customer requirements. Only after passing the test and issuing a detailed test report can the product be warehoused for shipment.

Dec. 25, 2025

Jingye New Energy | Helping High-Energy-Consumption Enterprises Achieve Green Energy Transition

In the global effort to address climate change, 'zero-carbon parks' have attracted attention. In the March 2025 government work report, it was proposed to build a batch of them, making them a focal point.

Nov. 20, 2025

The Tangshan Huaxi Special Steel Energy Storage Station 15MW/30.09MWh project has been connected to the grid and operated for 15 days, generating profits of over 300,000 yuan. The commercial application potential of energy storage technology in high-energy-consuming industries such as steel is gradually becoming apparent.

Nov. 20, 2025

The 22nd 'World Brand Conference and China Top 500 Most Valuable Brands Release' hosted by the World Brand Lab was held in Beijing on June 18, during which the 2025 'China Top 500 Most Valuable Brands' analysis report was released.

Let’s Get Started on Your New Energy Journey.

+86 0311 6736 8615

+86 150 3207 1231